The earth clamp (also known as the ground clamp or work clamp) is a crucial part of the welding setup, as it completes the electrical circuit for the welding process. Here's how and where it should be connected when welding:

1. Attachment to the Workpiece or Metal Surface

The earth clamp should be securely attached to the metal workpiece that you are welding. This provides the return path for the electrical current, completing the circuit between the welding machine and the work being welded.

Direct Contact: Ensure that the clamp has good, clean, and secure contact with the metal surface. If the metal surface is painted, rusted, or coated, the clamp may not make proper contact. Clean the area before attaching the clamp for optimal conductivity.

2. Grounding to the Welding Machine

The earth clamp connects to the negative terminal of the welding machine (in DC welding), or it may be part of the return path in AC systems. It works in conjunction with the welding electrode or welding torch, which is connected to the positive terminal, to form the full electrical circuit necessary for the welding process.

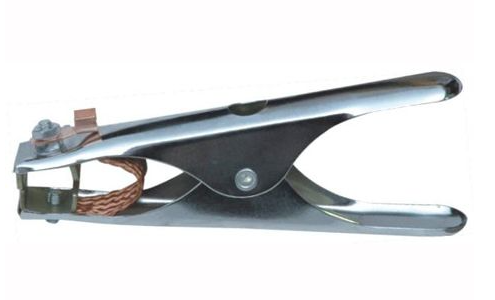

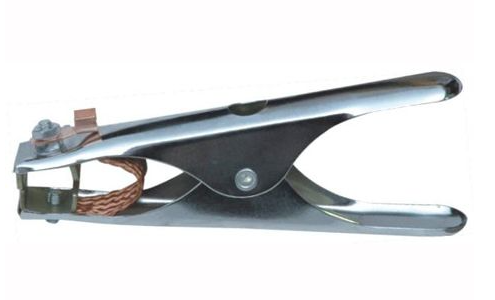

Earth Clamp

3. Importance of Location

The location where the earth clamp is placed is important for several reasons:

Prevents Welding Issues: If the earth clamp is not properly grounded, it can lead to issues like arc instability, poor weld quality, or electrical shocks.

Minimizes Resistance: The closer the clamp is to the weld area, the less resistance there will be in the electrical circuit, which helps improve welding efficiency and performance.

Safety: A well-grounded system reduces the risk of electrical hazards, including the risk of a shock or fire.

4. Best Practices

Secure Attachment: Ensure the clamp is firmly attached to a clean, bare metal surface.

Avoid Attachments to Moving Parts: Avoid clamping to moving parts, as this can cause erratic welding conditions and could be a safety hazard.

Avoid Small Parts: Don’t attach the earth clamp to small or thin parts that may not provide a sufficient return path, as this can lead to arc instability or poor welding results.

Conclusion

The earth clamp should be connected to the metal workpiece being welded, ensuring a secure and clean connection for the return current. Always verify that the clamp is properly grounded and attached to a conductive, non-painted surface for the best performance and safety.