Not all welders are created equally. Welding is a growing in-demand trade that can be a career for you. But welding is also a skill that you can use for everyday things such as creating garden art or décor. You can even use it to improve your current job, especially in the agriculture or auto industries. Welding has limitless possibilities depending on the kind of welding you are looking to learn.

There are four main types of welding. MIG – Gas Metal Arc Welding (GMAW), TIG – Gas Tungsten Arc Welding (GTAW), Stick – Shielded Metal Arc Welding (SMAW), and Flux-cored – Flux-cored Arc Welding (FCAW). We dive deeper into each type of welding here.

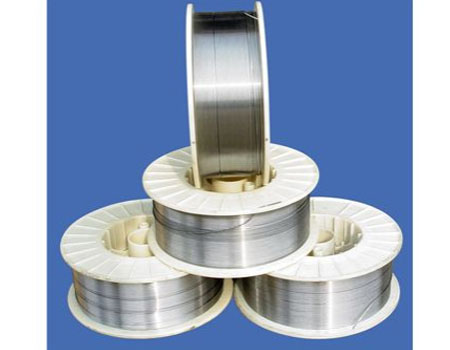

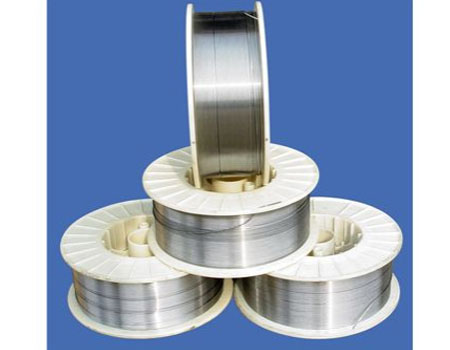

AWS A5.9 ER310

MIG – Gas Metal Arc Welding (GMAW)

MIG welding is used in the auto industry for repairing vehicle exhausts and is also used in creating homes and buildings. It is one of the most common types of welding. This is a type of arc welding that uses a continuous wire called an electrode. You will also use a shielding gas that travels through the welding gun and protects against contamination.

TIG – Gas Tungsten Arc Welding (GTAW)

TIG welding also uses electric arcs like MIG. When working with TIG welding, you use an electrode made of tungsten. Tungsten is one of the toughest metal materials. It will not dissolve or burn off. Welding can be done through a process known as fusion which is using or not using a filler metal. TIG also uses an external gas supply, such as argon or helium.

Aerospace and auto also use TIG welding as well as other industrial markets. This is also a great type of welding for Iowa as it can be very useful for farmers to use welding wagon frames, fenders and other important equipment.

Flux Cored Wire Gas-shielded

STICK – Shielded Metal Arc Welding (SMAW)

Want to take your welding to go? One big positive about Stick welding is that it’s portable. Stick welding is used in construction, maintenance and repair, underwater pipelines, and industrial fabrication.

For this type of welding, you will use shielded metal art welding more commonly known as Stick welding. You will use a consumable and protected electrode, or stick. The stick softens and combines metals by heating with an arc between a covered metal electrode and the base metal workpiece. As the stick melts, its protective cover also melts and shields the weld area from oxygen and other gases that may be in the air.

FLUX-CORED – Flux-cored Arc Welding (FCAW)

Flux-cored arc welding is similar to MIG welding because both use continuous wire and power supplies. You will combine a continuous electrode with a base metal. The electrode is a hollow tube filled with flux that is fed through the weld gun and into the weld pool. When welding outdoors, a flux shield offers protection against weather elements. This type of welding is used for welding thicker metals and is used in machining industries.

If you want to get more information about the types of welding, welcome to contact us today or request a quote.