Nickel and nickel alloys are chosen because of their:

corrosion resistance

heat resistance and high-temperature properties

low-temperature properties

Types of nickel alloys are identified and guidance is given on welding processes and techniques which can be used in fabricating nickel alloy components without impairing their corrosion or mechanical properties or introducing flaws into the weld.

Material types

The alloys can be grouped according to the principal alloying elements. Although there are National and International designations for the alloys, tradenames such as Inconel and Hastelloy, are more commonly used.

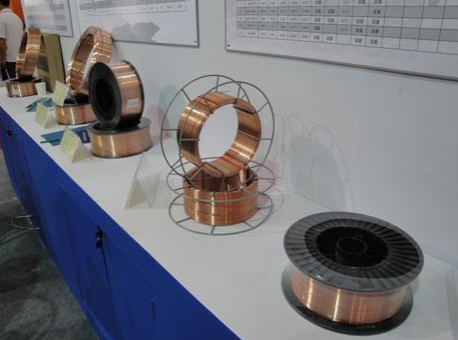

Mig Wire

In terms of their weldability, these alloys can be classified according to the means by which the alloying elements develop the mechanical properties, namely solid solution alloys, and precipitation-hardened alloys. A distinguishing feature of precipitation-hardened alloys is that mechanical properties are developed by heat treatment (solution treatment plus aging) to produce a fine distribution of particles in a nickel-rich matrix.

Solid solution alloys

Solid solution alloys are pure nickel, Ni-Cu alloys, and the simpler Fe-Ni-Cr alloys. These alloys are readily fusion welded, normally in the annealed condition. As the heat-affected zone (HAZ) does not harden, heat treatment is not usually required after welding.

Weldability

Most nickel alloys can be fusion welded using gas shielded processes like TIG or MIG. Of the flux processes, MMA is frequently used but the SAW process is restricted to solid solution alloys and is less widely used.

Solid solution alloys are normally welded in the annealed condition and precipitation hardened alloys in the solution treated condition. Preheating is not necessary unless there is a risk of porosity from moisture condensation. It is recommended that material containing residual stresses be solution-treated before welding to relieve the stresses.

GB ER50-3 AWS ER70S-3

Post-weld heat treatment is not usually needed to restore corrosion resistance but thermal treatment may be required for precipitation hardening or stress-relieving purposes to avoid stress corrosion cracking.

When using argon in TIG and MIG welding, attention must be paid to the shielding efficiency of the weld pool including the use of a gas backing system. In TIG welding, argon-hydrogen gas mixtures tend to produce cleaner welds.

Oxide inclusions and lack of inter-run fusion

As the oxide on the surface of nickel alloys has a much higher melting temperature than the base metal, it may remain solid during welding. Oxide trapped in the weld pool will form inclusions. In multi-run welds, oxide or slag on the surface of the weld bead will not be consumed in the subsequent run and may cause a lack of fusion imperfections.

Before welding, surface oxide, particularly if it has been formed at a high temperature, must be removed by machining or abrasive grinding; it is not sufficient to wire brush the surface as this serves only to polish the oxide. During multipass welding, surface oxide and slag must be removed between runs.

Weld metal solidification cracking

Factors that control solidification cracking include alloy, welding process, and welding conditions. For example, solidification cracking is a factor that limits the application of submerged arc welding, both with respect to applicable alloys and welding conditions. More generally, this type of cracking leads to restriction of weld shape, welding speed, and technique.