Understanding Wire Straightening and Cutting MachinesWire straightening and cutting machines are specialized equipment designed for the efficient processing of wire materials in various industries. These machines play a crucial role in enhancing the productivity of wire-related manufacturing processes by automating the tasks of straightening and cutting wires to specific lengths. This comprehensive guide provides insights into the functionality, applications, and benefits of wire straightening and cutting machines.

1. Functionality of Wire Straightening and Cutting Machines

Wire straightening and cutting machines are engineered to perform two primary functions:

Straightening: The machine straightens coiled or bent wire, ensuring it meets specific straightness requirements for downstream processes.

Cutting: After straightening, the machine precisely cuts the wire to the desired length. Some machines may offer additional features such as chamfering or bending capabilities.

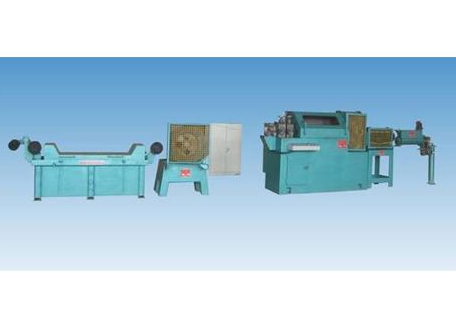

Wire Straightening and Cutting Machines

2. Working Mechanism

The working mechanism of wire straightening and cutting machines typically involves the following steps:

Feeding: Coiled wire is fed into the machine.

Straightening Rollers: The wire passes through a series of straightening rollers that remove bends and kinks, ensuring a straight output.

Cutting Mechanism: Once straightened, the wire is precisely cut to the required length by a cutting mechanism, often using blades or other cutting tools.

Output: The straightened and cut wire is then ready for use in various applications or further manufacturing processes.

3. Applications of Wire Straightening and Cutting Machines

Wire straightening and cutting machines find widespread use in industries that require processed wire materials, including:

Construction: For the production of straight and accurately sized reinforcement wires used in construction projects.

Fencing: Manufacturing of straight and uniform lengths of wire for fencing applications.

Automotive: Production of wires used in automotive components, such as springs and clips.

Mesh Manufacturing: Creating wire mesh with precise dimensions for applications like industrial filters and fencing.

Wire Straightening and Cutting Machines

4. Benefits of Wire Straightening and Cutting Machines

The use of wire straightening and cutting machines offers several advantages to manufacturers:

Enhanced Efficiency: Automation of the straightening and cutting process significantly increases production speed and efficiency.

Precision: These machines provide precise and accurate cutting, ensuring uniform lengths of wire with minimal wastage.

Customization: Adjustable settings on the machines allow for customization based on specific length and straightness requirements.

Reduced Labor Costs: Automation reduces the need for manual labor, contributing to cost savings and improved workplace safety.

Conclusion

Wire straightening and cutting machines are invaluable tools in industries that rely on processed wire materials. Their ability to efficiently straighten and cut wire with precision enhances overall manufacturing processes, leading to increased productivity and product quality in various applications.

Frequently Asked Questions about Wire Straightening and Cutting Machines

Q: Can wire straightening and cutting machines handle different types of wire?

A: Yes, many machines are designed to handle a variety of wire types, including steel, aluminum, and copper, with adjustments for different diameters.

Q: What safety measures should be considered when using these machines?

A: Operators should follow safety guidelines, including proper machine setup, wearing protective gear, and ensuring that the machine is equipped with safety features such as emergency stops.

Q: Are wire straightening and cutting machines suitable for small-scale operations?

A: Yes, there are machines available in different sizes to cater to various production scales, from small-scale operations to large industrial settings.