The installation, operation, and maintenance of arc welding equipment and the use of the procedures described in this document should only be carried out by qualified personnel in accordance with the applicable codes, safety practices, and the manufacturer's instructions.

Always ensure that the work area is clean and safe and that proper ventilation is used. Incorrect use of equipment and failure to comply with applicable codes and safety practices may result in serious personal injury and property damage.

Introduction

Oxygen/acetylene welding or "gas welding" is a process that relies on the combustion of oxygen and acetylene. When mixed together in the correct proportion in a hand-held torch or blowpipe, a hot flame with a temperature of approximately 3,200° is produced. The chemical action of the oxygen/acetylene flame can be adjusted by changing the volume ratio of oxygen to acetylene, using a valve on the torch or blowpipe.

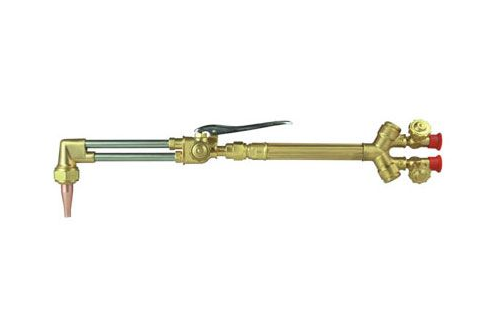

Gouging Torch

Equipment

The oxygen/acetylene equipment is portable and easy to use. It contains oxygen and acetylene gas stored under pressure in cylinders. The cylinder should be fitted with a regulator to control the pressure and flow of the gas. A flexible hose is used to connect the regulator to the torch or blowpipe. Between the hose and the regulator a specially designed safety device called a flame arrestor or "flashback arrester" is fitted. The flashback flame arrestor prevents the flame from the "flashback" from reaching the cylinder.

Flashback

Flashback is a rapid, high-pressure return of flame to a gas hose, caused by incorrect pressure settings under welding or cutting, or by clogged or overheated nozzles (for example, nozzles operating too close to the material).

Flashback can lead to extremely dangerous cylinder ignition and must be prevented by the correct use of a working flashback arrester.

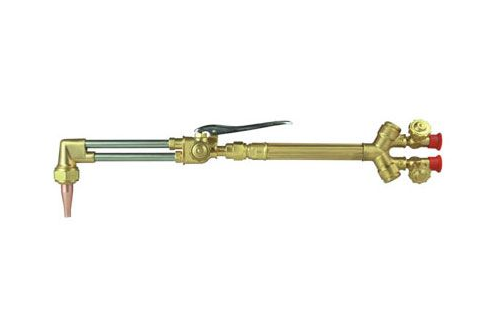

Welding Torch

Lighting procedures

To start oxygen/acetylene welding or cutting, open the diagram. The cylinder valve of the oxygen/acetylene unit is opened slowly by means of the cylinder key.

Do not open it suddenly as this may seriously damage the regulator and risk an accident. Open the cylinder valve spindle in only one turn. Open the gas control valve on the blowpipe and adjust the regulator to provide the correct working pressure, this ensures that any air or oxygen is removed from the hose. Repeat the process for the oxygen side.

Use a suitable torch to ignite the gas, ensuring that the torch is at right angle to the nozzle. Do not use a liquid igniter (e.g. cigarette lighter) as the vapor/gas combination can be dangerous.

Reduce or increase the supply of acetylene through the blowpipe valve until the flame stops smoking.

Slowly increase the oxygen through the blowpipe control valve until the white inner cone in the flame is clearly defined as the slightest haze of acetylene. The blowpipe is now correctly adjusted.

Hebei Machinery manufactory and export Welding Machinery, Welding Consumable and Welding Component for more than 20 years. The products include Welding Electrodes Production Line, Welding Machine, Plasma Welding Machine, Cutting Machine, Welding Torch, Cutting Torch, Welding Wire, Welding Electrodes, and relative Welding products. It is our great honor to satisfy your requirements for welding products. Any requirement from you will be maximized by us.

If you want to get more information about the oxy-acetylene welding techniques, welcome to contact us today or request a quote.