In welding, arc welding is the method of joining metals together using electricity that generates enough heat to melt the metal. An electric arc is created between the electrode and the base metal, melting the metal on contact. The electrode is used not only as a conductor of electricity for the base metal but also as a filler material for the weld.

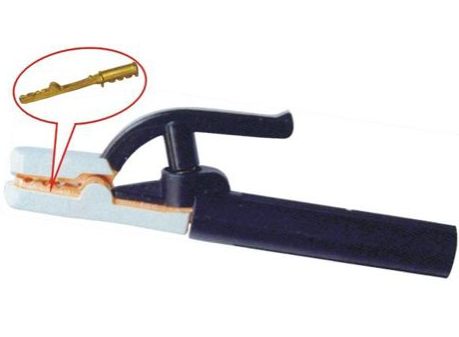

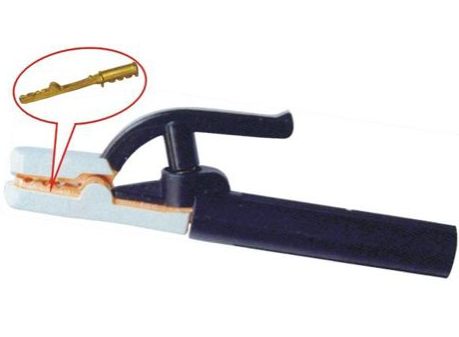

An electrode holder is a device used to hold the welding rod during the welding process. It is a clamping device that holds the electrode firmly enough to enable you to weld in a variety of positions. They are available in many different sizes and current capacities.

The electrode holder has an insulated handle through which the welding cable passes. Because it is insulated, there is no danger of a short circuit if any part of it comes into contact with your work. The electrode holder allows you to change electrodes quickly and easily while in use. Insulated and non-insulated electrode holders are available. Insulated electrode holders should always be used to reduce the risk of electric shock.

Welding Holder

How are the electrode holders rated?

Electrode holders are available in different sizes and each manufacturer has its own name for use. The holders are designed for a range of electrode diameters and a range of currents.

For larger electrode holders you will need a higher current rating. If the electrode holder is too small for the current being used, it will overheat and be damaged. Another thing to consider is that the larger the electrode, the easier it is to fatigue your hand when welding. Larger electrode holders are also more difficult to handle in different welding positions.

The electrode holder should be checked regularly to ensure that the springs and jaws are still strong. You should also assess your electrode holders to ensure that the insulation is in good condition. It is quite common that the electrode holders must be replaced regularly. Replacing the welding holder is a fairly simple task.

Welding Holder

How do I change the electrode holder?

The following are the steps to use when attempting to replace the electrode holder.

Before replacing the electrode holder, refer to the manufacturer's instructions.

You should always ensure that the power to the welding machine is switched off and unplugged.

Loosen the screw that slides the insulator onto the cable.

Loosen the nut holding the electrode cable in the electrode clamp, remove the jaw insulator cover, remove the wire and pull the handle off the cable.

Remove the handle from the new electrode holder and slide it onto the new electrode cable (make sure the correct side is facing up).

Reconnect the welder to the power supply.

Perform a test to see if the electrode holder is now correctly fitted.

For more information on electrode holders and safety, please see OSHA's regulations on electrode holders here.

Earth Clamp

Other notes

You should regularly check the insulators around the electrodes to ensure they are not damaged.

You should not use electrodes that are less than 2 inches in length. Depleting the electrode to the endpoint will burn the insulation. It may also increase your chances of electric shock as the arc may jump onto the electrode holder or damage it due to high temperatures.

Never immerse the electrode holder in water to allow it to cool.

Never place the electrode holder on a conductive surface.

Never touch electrode holders connected to 2 different welders at the same time.

Of course, never touch anyone with the electrode holder.

If you want to get more information about the welding electrode holders, welcome to contact us today or request a quote.