Type ER70S-2 is the most popular Tig rod for welding carbon and low alloy steels and is a triple deoxidizing steel wire used for both TIG and MIG welding applications. Type ER70S-6 is also available in cut lengths for purchase and is a very popular MIG wire for TIG welding.

What does er70s 6 mean?

ER70S6 wire meets AWS A5.18 specifications. The designations are as follows: ER indicates the filler metal that can be used as an electrode or rod. 70 indicates the minimum tensile strength in 1000 psi increments when tested in accordance with this specification for the weld metal produced by the electrode.

AWS ER70S-6

What does er70s 2 mean?

er70s 2 is a composite deoxidizing wire that contains small amounts of zirconium, titanium, and aluminum in addition to the manganese and silicon deoxidizers characteristic of the wire set. er70s 2 is widely used for staggered welding of small diameter wires that utilize short-circuit arc type transfer.

ER70S2 vs ER70S6 wire/rod: Which is better?

ER70S2 vs ER70S6

Both ER70S2 and ER70S6 are MIG and TIG compatible electrodes that can be used for all light welding applications such as sheet metal and tube work. These wires have nearly identical specifications except for the better yield and tensile strength of ER70S6. The higher silicon content in ER70S6 allows the filler metal to be more fluid than other filler metals and appears to float the oxide to the surface, providing a better weld on blocked surfaces.

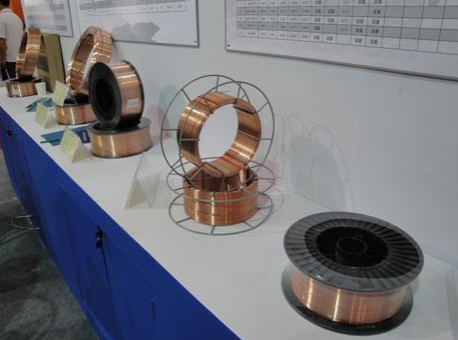

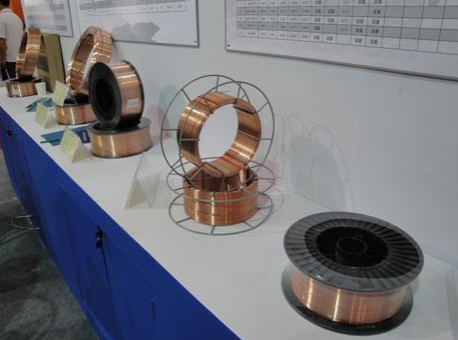

Welding wire is a metal rod that is used to create a heated arc that joins two metal workpieces together.

Welding wire can be of different types and is used in various welding processes.

Welding wire is a gas shielded electrode with a variety of mechanical and chemical properties, arc behavior, quality, and cost.

Flux Cored Wire Gas-shielded

The three main types of welding wire are

Solid gas shielded metal arc welding (GMAW) wire

Composite GMAW (metal cored) wire

Gas shielded flux-cored arc welding (FCAW) wire

Wires are also available in a variety of diameters and are typically selected based on the welder and work material being used.

ER70S2 Overview

ER70S-2 wire is a triple deoxidized wire containing zirconium, titanium, and aluminum as well as silicon and manganese.

This wire can be used for both TIG and MIG welding processes. The wire is also suitable for all welding positions. ER70S2 can be used to obtain x-ray quality welds on most surfaces. The wire can also be used for post-weld heat treatment operations.

After stress relieving at 590 - 620 ° C (1100 - 1150 ° F) for 8 hours, it can exceed 482 MPa (70 ksi) tensile strength and 400 MPa (58 ksi) yield strength.

Benefits

Can be used for MIG and TIG welds

Good yield and tensile strengths

High density

Low spatter

Full-length inkjet print markings

Restrictions

Efforts to weld contaminated surfaces

ER70S6 Overview

ER70S6 is a general-purpose welding wire used for a variety of fabrication work typically performed on mild steel. This wire contains more deoxidizer than other wires in its class.

It is typically compatible with a 75:25 ratio of argon and carbon dioxide shielding gas. The wire can also be used with 100% carbon dioxide or a higher percentage of argon gas.

The welder contributes to improved melt pool fluidity and excellent wetting action, resulting in an aesthetically pleasing welding process.

The welder has a tensile strength range of 80,000 to 90,000 and a tensile yield strength range of 65,000 to 75,000 psi, both parameters discussed being influenced by the gas and composition used.

Benefits

Can be used in MIG and TIG welds

More puddle flow

Excellent wetting action

Can weld contaminated or rusted surfaces

Good yield and tensile strengths

Limitations

More expensive than some of its counterparts

This wire is primarily used for single-pass welding on surfaces where rust and contaminants are prevalent prior to the welding process. The higher content of manganese and silicon deoxidizer allows

ER70S6 is suitable for repairing mild and low-alloy steel, light pipe, and tubing, various sheet metal applications, and root weld channel welding.