A welding torch can be an important tool in the field of metal joining, especially for high-volume operations. It increases the efficiency of the welding process, keeps professional welders comfortable while working, and encourages a neater weld surface.

What types of welding guns are available?

Different types of welding torches exist, each designed differently depending on the welding process.

The main fusion welding processes are SMAW (shielded metal arc welding, also known as stick welding), MIG (metal inert gas), FCAW (flux cored arc welding), and TIG (tungsten inert gas shielded welding).

Each welding process relies on a specific tool, not all of which use a torch. For example, TIG welding and stick welding are manual processes in which the welder holds a stick electrode.

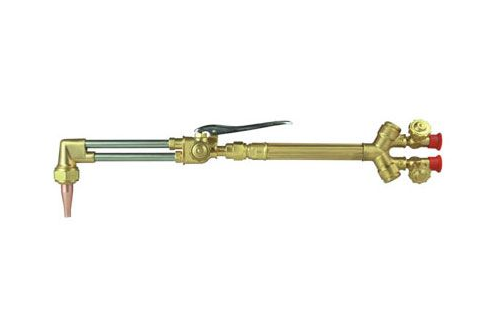

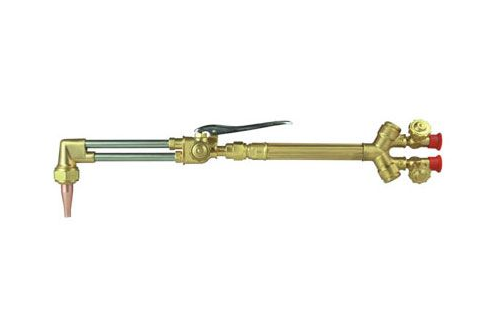

Welding Torch

Arc Welding torches

Arc welding torches facilitate the discharge between the electrode wire and the metal workpiece. These guns guide the electrode into the arc, and some include the additional feature of shielding or starting the arc.

Spot Welding torches

A torch for resistance spot welding (RSW) has a main housing that contains an installed cylinder that compresses the necessary electrodes.

RSW welding is not liquid welding. The pressure and heat generated by the current resistance are used to fuse two pieces of metal together through a precise point of the liquefied metal. For this reason, guns for RSW are unique in their design.

MIG Torch

How does a welding torch work?

Welders can use welding torches in many types of processes, including spot welding, arc welding, and electron beam welding. The way a welding gun works varies depending on the particular welding process.

For example, a MIG torch works with a wire feed system that continuously supplies the torch with electrode wire from a spool of wire. The gun is connected to a power source, usually a welder. The handheld unit delivers current to the wire through a conductive nozzle while distributing shielding gas to protect the molten pool and arc.

What are welding torches used for?

The welding torch is used in automatic welding systems to guide the welding rod into the arc, conduct welding power to the rod, and to protect the arc zone. There are many types of welding torches and the choice depends on the welding process, the variation of the welding process, the welding current, the electrode size, and the shielding medium.

Welding guns are used for many types of welding: spot welding and different forms of arc welding, such as flux-cored or MIG welding. You'll find them used in industries that rely on metal connections for everyday work or production processes, such as automotive, agricultural equipment, and railroad car manufacturing.

Welding torches can be used in challenging operating conditions. For example, these torches can be used to weld on orbiting spacecraft.