Introduction:The heat resistant steel welding wires produced by the company has the features of high impact toughness, hot crack resistance and anti-oxidation, and are mainly applied to high-temperature operations, for example, welding of high-temperature pressure containers, pipes, etc.

Application:It is applied to high-temperature operation of 12CrMoV, 15Cr1MoV, typically the welding of heat resistant steel pressure containers and pipes.

|

Name

|

TB Model

|

Specification(mm)

|

Package(kg)

|

The main purpose

|

|

ER44-8

|

TB/T H08MnSiCuCrNiⅠ

|

1.0-2.0

|

15-20

|

For the 44kg class of weathering steel welding.

|

|

TB/T H08MnSiCuCrNiⅡ

|

1.0-2.0

|

15-20

|

For the 44kg class of weathering steel welding.

|

Standard &Typical Chemical Composition of Deposited Metal (%)

|

Model

|

Chemical Composition of Fused Metal(%)

|

Mechanical Property of Fused Metal

|

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Ni

|

Cu

|

Yield Strength (MPa)

|

Tensile Strength (MPa)

|

Elongation Rate(%)

|

Ballistic Work (J)

|

|

H08MnSiCuCrNiⅠ

|

0.07

|

1.12

|

0.50

|

0.016

|

0.013

|

0.30

|

0.35

|

0.21

|

391

|

491

|

28

|

41(-40℃)

|

|

H08MnSiCuCrNiⅡ

|

0.08

|

1.01

|

0.42

|

0.017

|

0.012

|

0.28

|

0.31

|

0.23

|

401

|

502

|

27

|

39(-40℃

|

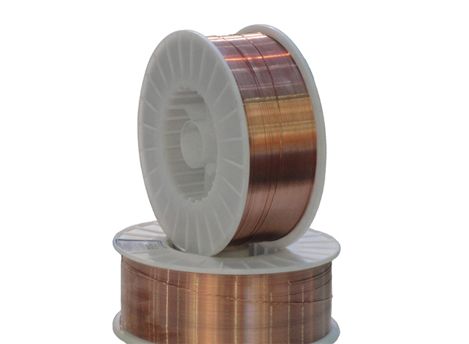

Packing: 15kg/spool