Introduction:HBW-50C3 is a kind of gas shielded carbon steel copper-plated welding wire, CO2 or rich argon gas can be used for shielding in welding. It is suitable for single pass welding or multiple pass welding and has excellent welding process performance, less splashing, good formation of weld seams and high crack resistance. It is particularly suitable for thin-plate small-current high-speed welding.

Application: It is applied to welding of carbon steel (for example, Q215, Q195, etc.) and partial low alloy steel (for example, 12Mn) in bridges, automobiles, pipe fittings, etc.

Chemical Compositions of Welding Wire:%

|

-

|

C

|

Mn

|

Si

|

P

|

S

|

Ni

|

Cr

|

Cu

|

Mo

|

V

|

|

Example Value

|

0.09

|

1.05

|

0.65

|

0.014

|

0.013

|

0.02

|

0.017

|

0.17

|

0.004

|

0.003

|

|

Range

|

0.06-0.15

|

0.90-1.40

|

0.45-0.75

|

≤0.025

|

≤0.025

|

≤0.15

|

≤0.15

|

≤0.50

|

≤0.15

|

≤0.03

|

Note: The copper in the welding wire is the summation of the copper in the copper coating and the self-contained copper.

Fused Metal Mechanical Property:

|

-

|

Tensile Strength

Rm(MPa)

|

Yield Strength

(MPa)Rp0.2

|

Elongation Rate

A(%)

|

Ballistic Work Room Temperature

-20℃ AKV(J)

|

Protective Gas

|

|

Example Value

|

520

|

437

|

29

|

116

|

CO2(Purity

≥99.5%)

|

|

553

|

441

|

28

|

136

|

Argon-rich

|

|

Range

|

≥500

|

≥420

|

≥22

|

≥27

|

-

|

Welding Process:

|

Welding Wire Diameter

|

Wire Feeding Speed(mm/s)

|

Electric Arc Voltage(V)

|

Welding Current(A)

|

Polarity

|

Distance Between Electrode Tip and Work piece(mm)

|

Welding Speed(mm/s)

|

|

1.2

|

190±10

|

27-32

|

260-290

|

DC+

|

19±3

|

5.5±1.0

|

|

1.6

|

100±5

|

25-30

|

330-360

|

DC+

|

22±3

|

5.5±1.0

|

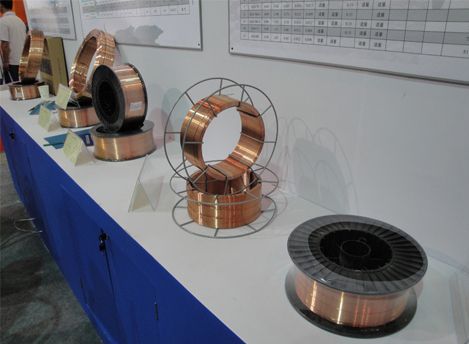

Packing: 5kg/spool/box, 15kg/spool/box

Note: 1. Welding wires of other specifications can refer to the standards, and proper changes may be required according to actual needs;

2. While welding, the use performance of welding wires and the mechanical property of fused metal will be affected if it is off the standards.