Introduction:HBWH-70G-1 700MPa grade high strength copper wire, using rich argon gas protection, through the low C,

high Mn, Ti, Cr processing and Ni alloy elements such as solid solution strengthening, grain refinement, the weld seam with

high strength and high toughness, and stable arc, little splash, and can be suitable for the full range of welding.

Widely used in the welding of coal mine machinery, heavy machinery, vehicles, shipbuilding, container and other 700MPa grade

high strength steel and low alloy structural steel (such as Q500, Q550) .

Fused Metal Mechanical Property:

|

-

|

Tensile Strength

Rm(MPa)

|

Yield Strength

(MPa)Rp0.2

|

Elongation Rate

A(%)

|

Ballistic Work

-20℃ AKV(J)

|

Protective Gas

|

|

Example Value

|

745

|

649

|

20

|

117

|

Argon-rich gas

|

|

Range

|

≥700

|

≥620

|

≥16

|

≥47

|

- |

Welding Process:

|

Welding Wire Diameter

|

Wire Feeding Speed(mm/s)

|

Electric Arc Voltage (V)

|

Welding Current (A)

|

Polarity

|

Distance Between Electrode Tip and Workpiece(mm)

|

Welding Speed(mm/s)

|

|

1.2

|

190±10

|

27~32

|

260~290

|

DC+

|

19±3

|

5.5±1.0

|

|

1.6

|

100±5

|

25~30

|

330~360

|

DC+

|

22±3

|

5.5±1.0

|

Note:

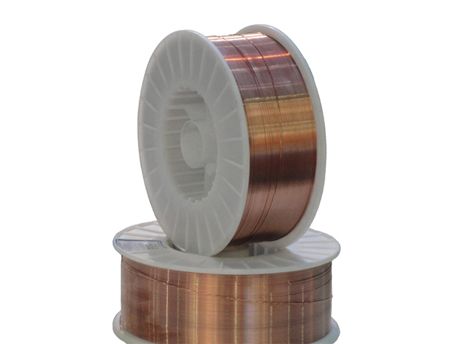

1.Packing: 15kg/spool/box

2. Welding wires of other specifications can refer to the standards, and proper changes may be required according to actual needs;

3. While welding, the use performance of welding wires and the mechanical property of fused metal will be affected if it is off the standards.