Introduction:Suitable for fabricating pipes of supercritical steam turbines and boilers ,which made by martensite heatre sisting steels. Both preheating and interpass temperature should be 232-288℃ and the weld zone should be tempered at 730-760℃ for 6 hours after welding.

Standard & Typical Chemical Composition of Deposited Metal (%)

|

Chemical Composition

|

C

|

Mn

|

Si

|

S

|

P

|

Cr

|

Ni

|

Mo

|

V

|

Cu

|

Other

|

|

Specification

|

0.08-0.13

|

≤1.20

|

≤0.30

|

≤0.01

|

≤0.01

|

8.00-10.50

|

≤0.80

|

0.85-1.20

|

0.15-0.30

|

Cu≤0.25

|

N0.02-0.07

|

Nb 0.02-0.10

|

Al≤0.04

|

|

Actual result

|

0.094

|

0.75

|

0.22

|

0.004

|

0.009

|

9.32

|

0.66

|

1.03

|

0.208

|

0.02

|

0.03

|

0.053

|

0.005

|

Standard & Typical Mechanical Properties of Deposited Metal

|

Test Item

|

Postweld Condition

|

Yield Point ReL (MPa)

|

Tensile Strength Rm(MPa)

|

Elongation A4(%)

|

Akv Value (J)

|

|

Specification

|

PWHT

760℃X6h

|

≥530

|

≥620

|

≥17

|

-

|

|

Actual Result

|

630

|

740

|

21

|

25℃ 80

|

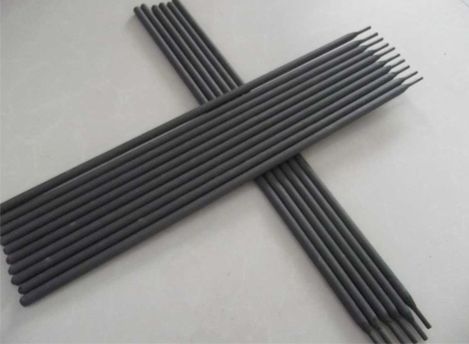

Size and Current (DC +)

|

Dia.(mm)

|

2.5

|

3.2

|

4.0

|

5.0

|

|

Length(mm)

|

300

|

350

|

350

|

350

|

|

Current(A)

|

70-90

|

80-110

|

140-160

|

160-200

|